UL Industrial Cables XHHW/CPE, 600V, Type TC Control Cable

| Availability: | |

|---|---|

| Quantity: | |

UL Industrial Cables XHHW/CPE, 600V, Type TC Control Cable

| Application and Description | XHHW/CPE type TC Control Cable is for use in industrial power or control circuits where small diameter, flame retardant cables are desired. Primary installations include cable trays, raceways, and outdoor locations where supported by a messenger wire. Type TC Control Cable is also listed for direct burial and for use in Class 1, Division 2 hazardous locations and Class 1 control circuits. Constructions witd 3 or more conductors are listed for exposed runs (TC-ER) per NEC 336.10.Conductors may be used in wet or dry locations at temperatures not to exceed 90°C. |

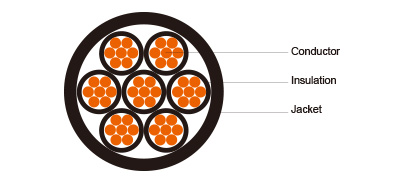

| Cable Construction | |

| Conductor | Stranded bare annealed copper, available in size AWG14, 12, 10(Type XHHW-2) |

| Insulation | Flame-retardant and moisture resistant Cross-Linked Polyetdylene (FRXLPE) |

| Jacket | Flame retardant, moisture and sunlight resistant CPE (PVC/LSOH is available upon request) |

| Color | upon request, black is preferable |

| Technical Characteristics | - UL 1277 - Electrical Power and Control Tray Cables - UL 1685 - UL Flame Exposure Test (70,000 Btu/hr) - ICEA S-58-679 - Control Cable Conductor Identification Metdod 1, Table 2 - IEEE 1202 - Flame Testing of Cables for Use in Cable Tray in Industrial and Commercial Occupancies (70,000 Btu/hr) |

Cable Parameter

NO.OF CORES | NOMINAL JACKET THICKNESS INCH/MM | NOMINAL OVERALL DIAMETER INCH/MM | CABLE WEIGHT LBS/KFT KG/KM | |||

AWG 14 (7 strands) | ||||||

2 | 0.045 | 1.14 | 0.349 | 8.86 | 62 | 92 |

3 | 0.045 | 1.14 | 0.370 | 9.40 | 85 | 127 |

4 | 0.045 | 1.14 | 0.403 | 10.24 | 104 | 155 |

5 | 0.045 | 1.14 | 0.440 | 11.18 | 123 | 183 |

7 | 0.045 | 1.14 | 0.479 | 12.17 | 163 | 242 |

9 | 0.060 | 1.52 | 0.588 | 14.94 | 220 | 327 |

12 | 0.060 | 1.52 | 0.659 | 16.74 | 282 | 419 |

15 | 0.060 | 1.52 | 0.730 | 18.54 | 343 | 511 |

19 | 0.060 | 1.52 | 0.768 | 19.51 | 420 | 624 |

25 | 0.080 | 2.03 | 0.938 | 23.83 | 576 | 857 |

37 | 0.080 | 2.03 | 1.067 | 27.10 | 811 | 1206 |

AWG 12 (7 strands) | ||||||

2 | 0.045 | 1.14 | 0.384 | 9.75 | 84 | 125 |

3 | 0.045 | 1.14 | 0.408 | 10.36 | 114 | 169 |

4 | 0.045 | 1.14 | 0.445 | 11.30 | 145 | 216 |

5 | 0.045 | 1.14 | 0.487 | 12.37 | 170 | 252 |

7 | 0.060 | 1.52 | 0.562 | 14.27 | 241 | 358 |

9 | 0.060 | 1.52 | 0.651 | 16.54 | 303 | 452 |

12 | 0.060 | 1.52 | 0.732 | 18.59 | 392 | 583 |

15 | 0.060 | 1.52 | 0.813 | 20.65 | 480 | 714 |

19 | 0.080 | 2.03 | 0.896 | 22.76 | 622 | 925 |

25 | 0.080 | 2.03 | 1.043 | 26.49 | 804 | 1196 |

37 | 0.080 | 2.03 | 1.190 | 30.23 | 1144 | 1702 |

AWG 10 (7 strands) | ||||||

2 | 0.045 | 1.14 | 0.431 | 10.95 | 114 | 170 |

3 | 0.045 | 1.14 | 0.459 | 11.66 | 159 | 236 |

4 | 0.045 | 1.14 | 0.502 | 12.75 | 204 | 303 |

5 | 0.060 | 1.52 | 0.581 | 14.76 | 257 | 382 |

7 | 0.060 | 1.52 | 0.632 | 16.05 | 342 | 510 |

9 | 0.060 | 1.52 | 0.736 | 18.69 | 433 | 645 |

12 | 0.080 | 2.03 | 0.870 | 22.10 | 593 | 883 |

15 | 0.080 | 2.03 | 0.964 | 24.49 | 726 | 1081 |

UL Industrial Cables XHHW/CPE, 600V, Type TC Control Cable

| Application and Description | XHHW/CPE type TC Control Cable is for use in industrial power or control circuits where small diameter, flame retardant cables are desired. Primary installations include cable trays, raceways, and outdoor locations where supported by a messenger wire. Type TC Control Cable is also listed for direct burial and for use in Class 1, Division 2 hazardous locations and Class 1 control circuits. Constructions witd 3 or more conductors are listed for exposed runs (TC-ER) per NEC 336.10.Conductors may be used in wet or dry locations at temperatures not to exceed 90°C. |

| Cable Construction | |

| Conductor | Stranded bare annealed copper, available in size AWG14, 12, 10(Type XHHW-2) |

| Insulation | Flame-retardant and moisture resistant Cross-Linked Polyetdylene (FRXLPE) |

| Jacket | Flame retardant, moisture and sunlight resistant CPE (PVC/LSOH is available upon request) |

| Color | upon request, black is preferable |

| Technical Characteristics | - UL 1277 - Electrical Power and Control Tray Cables - UL 1685 - UL Flame Exposure Test (70,000 Btu/hr) - ICEA S-58-679 - Control Cable Conductor Identification Metdod 1, Table 2 - IEEE 1202 - Flame Testing of Cables for Use in Cable Tray in Industrial and Commercial Occupancies (70,000 Btu/hr) |

Cable Parameter

NO.OF CORES | NOMINAL JACKET THICKNESS INCH/MM | NOMINAL OVERALL DIAMETER INCH/MM | CABLE WEIGHT LBS/KFT KG/KM | |||

AWG 14 (7 strands) | ||||||

2 | 0.045 | 1.14 | 0.349 | 8.86 | 62 | 92 |

3 | 0.045 | 1.14 | 0.370 | 9.40 | 85 | 127 |

4 | 0.045 | 1.14 | 0.403 | 10.24 | 104 | 155 |

5 | 0.045 | 1.14 | 0.440 | 11.18 | 123 | 183 |

7 | 0.045 | 1.14 | 0.479 | 12.17 | 163 | 242 |

9 | 0.060 | 1.52 | 0.588 | 14.94 | 220 | 327 |

12 | 0.060 | 1.52 | 0.659 | 16.74 | 282 | 419 |

15 | 0.060 | 1.52 | 0.730 | 18.54 | 343 | 511 |

19 | 0.060 | 1.52 | 0.768 | 19.51 | 420 | 624 |

25 | 0.080 | 2.03 | 0.938 | 23.83 | 576 | 857 |

37 | 0.080 | 2.03 | 1.067 | 27.10 | 811 | 1206 |

AWG 12 (7 strands) | ||||||

2 | 0.045 | 1.14 | 0.384 | 9.75 | 84 | 125 |

3 | 0.045 | 1.14 | 0.408 | 10.36 | 114 | 169 |

4 | 0.045 | 1.14 | 0.445 | 11.30 | 145 | 216 |

5 | 0.045 | 1.14 | 0.487 | 12.37 | 170 | 252 |

7 | 0.060 | 1.52 | 0.562 | 14.27 | 241 | 358 |

9 | 0.060 | 1.52 | 0.651 | 16.54 | 303 | 452 |

12 | 0.060 | 1.52 | 0.732 | 18.59 | 392 | 583 |

15 | 0.060 | 1.52 | 0.813 | 20.65 | 480 | 714 |

19 | 0.080 | 2.03 | 0.896 | 22.76 | 622 | 925 |

25 | 0.080 | 2.03 | 1.043 | 26.49 | 804 | 1196 |

37 | 0.080 | 2.03 | 1.190 | 30.23 | 1144 | 1702 |

AWG 10 (7 strands) | ||||||

2 | 0.045 | 1.14 | 0.431 | 10.95 | 114 | 170 |

3 | 0.045 | 1.14 | 0.459 | 11.66 | 159 | 236 |

4 | 0.045 | 1.14 | 0.502 | 12.75 | 204 | 303 |

5 | 0.060 | 1.52 | 0.581 | 14.76 | 257 | 382 |

7 | 0.060 | 1.52 | 0.632 | 16.05 | 342 | 510 |

9 | 0.060 | 1.52 | 0.736 | 18.69 | 433 | 645 |

12 | 0.080 | 2.03 | 0.870 | 22.10 | 593 | 883 |

15 | 0.080 | 2.03 | 0.964 | 24.49 | 726 | 1081 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.