Type W Single Conductor Portable Power Cable 2kV

Type W Single Conductor Portable Power Cable 2kV

| Applications | These cables are designed for use on electric mining locomotives and other mobile equipment of the gathering-reel type, where the cable must withstand constant flexing and reeling. |

| Standards | ICEA S-75-381/NEMA WC 58 ASTM B 172 ASTM B 33 CAN/CSA C22.2 No.96 |

| Construction | |

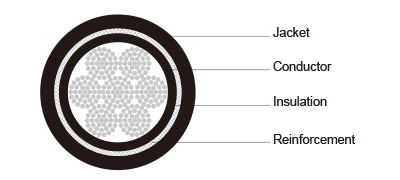

| Conductors | Stranded annealed tinned copper conductor. |

| Insulation | Ethylene Propylene Rubber (EPR). |

| Reinforcement | A layer of polyester braid, applied between the insulation and jacket for mechanical strength. |

| Jacket | Heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

| Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon reques. Two-layer jacket with reinforcing fibre between the two layers can be offered as an option. |

| Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD Maximum Operating Temperature: +90℃ |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A | |

1×8 | 133 | 0.060 | 1.5 | 0.060 | 1.5 | 0.44 | 11.2 | 150 | 223 | 83 |

1×6 | 168 | 0.060 | 1.5 | 0.080 | 2.0 | 0.51 | 13.0 | 205 | 305 | 109 |

1×4 | 259 | 0.060 | 1.5 | 0.080 | 2.0 | 0.57 | 14.5 | 280 | 417 | 145 |

1×3 | 329 | 0.060 | 1.5 | 0.095 | 2.4 | 0.63 | 16.0 | 350 | 521 | 167 |

1×2 | 259 | 0.060 | 1.5 | 0.095 | 2.4 | 0.66 | 16.8 | 370 | 550 | 192 |

1×1 | 329 | 0.080 | 2.0 | 0.110 | 2.8 | 0.74 | 18.8 | 500 | 744 | 223 |

1×1/0 | 259 | 0.080 | 2.0 | 0.110 | 2.8 | 0.77 | 19.6 | 550 | 818 | 258 |

1×2/0 | 329 | 0.080 | 2.0 | 0.110 | 2.8 | 0.82 | 20.1 | 660 | 982 | 298 |

1×3/0 | 427 | 0.080 | 2.0 | 0.125 | 3.2 | 0.87 | 22.1 | 830 | 1235 | 345 |

1×4/0 | 532 | 0.080 | 2.0 | 0.125 | 3.2 | 0.93 | 23.6 | 950 | 1413 | 400 |

1×250 | 608 | 0.095 | 2.4 | 0.140 | 3.6 | 1.03 | 26.2 | 1240 | 1845 | 445 |

1×300 | 741 | 0.095 | 2.4 | 0.140 | 3.6 | 1.09 | 27.7 | 1400 | 2083 | 500 |

1×350 | 855 | 0.095 | 2.4 | 0.155 | 3.9 | 1.15 | 29.2 | 1480 | 2202 | 552 |

1×500 | 1221 | 0.095 | 2.4 | 0.155 | 3.9 | 1.31 | 33.3 | 2140 | 3184 | 695 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.

Type W Single Conductor Portable Power Cable 2kV

| Applications | These cables are designed for use on electric mining locomotives and other mobile equipment of the gathering-reel type, where the cable must withstand constant flexing and reeling. |

| Standards | ICEA S-75-381/NEMA WC 58 ASTM B 172 ASTM B 33 CAN/CSA C22.2 No.96 |

| Construction | |

| Conductors | Stranded annealed tinned copper conductor. |

| Insulation | Ethylene Propylene Rubber (EPR). |

| Reinforcement | A layer of polyester braid, applied between the insulation and jacket for mechanical strength. |

| Jacket | Heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

| Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon reques. Two-layer jacket with reinforcing fibre between the two layers can be offered as an option. |

| Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD Maximum Operating Temperature: +90℃ |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A | |

1×8 | 133 | 0.060 | 1.5 | 0.060 | 1.5 | 0.44 | 11.2 | 150 | 223 | 83 |

1×6 | 168 | 0.060 | 1.5 | 0.080 | 2.0 | 0.51 | 13.0 | 205 | 305 | 109 |

1×4 | 259 | 0.060 | 1.5 | 0.080 | 2.0 | 0.57 | 14.5 | 280 | 417 | 145 |

1×3 | 329 | 0.060 | 1.5 | 0.095 | 2.4 | 0.63 | 16.0 | 350 | 521 | 167 |

1×2 | 259 | 0.060 | 1.5 | 0.095 | 2.4 | 0.66 | 16.8 | 370 | 550 | 192 |

1×1 | 329 | 0.080 | 2.0 | 0.110 | 2.8 | 0.74 | 18.8 | 500 | 744 | 223 |

1×1/0 | 259 | 0.080 | 2.0 | 0.110 | 2.8 | 0.77 | 19.6 | 550 | 818 | 258 |

1×2/0 | 329 | 0.080 | 2.0 | 0.110 | 2.8 | 0.82 | 20.1 | 660 | 982 | 298 |

1×3/0 | 427 | 0.080 | 2.0 | 0.125 | 3.2 | 0.87 | 22.1 | 830 | 1235 | 345 |

1×4/0 | 532 | 0.080 | 2.0 | 0.125 | 3.2 | 0.93 | 23.6 | 950 | 1413 | 400 |

1×250 | 608 | 0.095 | 2.4 | 0.140 | 3.6 | 1.03 | 26.2 | 1240 | 1845 | 445 |

1×300 | 741 | 0.095 | 2.4 | 0.140 | 3.6 | 1.09 | 27.7 | 1400 | 2083 | 500 |

1×350 | 855 | 0.095 | 2.4 | 0.155 | 3.9 | 1.15 | 29.2 | 1480 | 2202 | 552 |

1×500 | 1221 | 0.095 | 2.4 | 0.155 | 3.9 | 1.31 | 33.3 | 2140 | 3184 | 695 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.