PVC SHEATH FLAME RETARDANT CABLE TO IEC60332 300/500V PVC Insulated, PVC Sheathed Power Cables (2-5 Cores)

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

| Availability: | |

|---|---|

| Quantity: | |

PVC SHEATH FLAME RETARDANT CABLE TO IEC60332 300/500V PVC Insulated, PVC Sheathed Power Cables (2-5 Cores)

05VV-K (CU/PVC/PVC 300/500V Class 5)

BS Code: 3182Y/3183Y/3184Y/3185Y

HAR Code: H05VV-F

| Application: | The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. |

| STANDARDS: | Basic design to BS EN 50525-2-11(formerly BS 6500) |

| Fire Performance: | Flame Retardance (Single Vertical Wire Test) EN 60332-1-2 |

| Voltage Rating: | 300/500V |

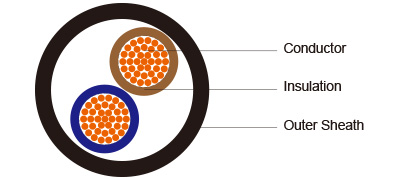

| Conductor | Flexible copper wire according to EN 60228 class 5. |

| Insulation | PVC type TI 2 according to EN 50363-3. |

| Filling | For circular cable having two cores, the space between the cores shall be filled either by separate fillers or by the sheath filling the interstices. For circular cables with three, four or five cores, a centre filler may be used. |

| Outer Sheath | PVC type TM 2 according to EN 50363-4-1. A tape may be applied around the core assembly before application of the sheath. |

| Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour

Cables and cords with a green-and-yellow cores

| No. of cores | Colour of coresb | ||||

| Protective | Live | ||||

| 3 Cores | Yellow/Green | Blue | Brown | ||

| 4 Cores | Yellow/Green | - | Brown | Black | Grey |

| 4 Coresa | Yellow/Green | Blue | Brown | Black | |

| 5 Cores | Yellow/Green | Blue | Brown | Black | Grey |

| a For certain applications only. | |||||

| b In this table an uninsulated concentric conductor, such as a metallic sheath, armour or screen wire, is not regarded as a core. A concentric conductor is identified by its position and, therefore, need not be identified by colour. | |||||

Cables and cords without a green-and-yellow cores

| No. of cores | Colour of coresb | ||||

| 2 Cores | Blue | Brown | |||

| 3 Cores | - | Brown | Black | Grey | |

| 3 Coresa | Blue | Brown | Black | ||

| 4 Cores | Blue | Brown | Black | Grey | |

| 5 Cores | Blue | Brown | Black | Grey | Black |

| a For certain applications only. | |||||

| b In this table an uninsulated concentric conductor, such as a metallic sheath, armour or screen wire, is not regarded as a core. A concentric conductor is identified by its position and, therefore, need not be identified by colour. | |||||

Sheath Colour: Black (other colors upon request)

Physical And Thermal Properties

| Maximum temperature range during operation (PVC) | 60°C |

| Maximum short circuit temperature (5 Seconds) | 150°C |

| Minimum bending radius | Up to 12mm²: 3 x overall diameter |

| Above 12mm²: 4 x overall diameter |

Construction Parameters

| No. of Core X Cross Section | ||||

| Nominal Insulation Thickness | Nominal Sheath Thickness | Maximum Overall Diameter | Approx. Weight | |

| Noxmm2 | mm | mm | mm | kg/km |

| 2x0.75 | 0.6 | 0.8 | 7.2 | 57 |

| 2x1.0 | 0.6 | 0.8 | 7.5 | 65 |

| 2x1.5 | 0.7 | 0.8 | 8.6 | 87 |

| 2x2.5 | 0.8 | 1.0 | 10.6 | 134 |

| 2x4 | 0.8 | 1.1 | 12.1 | 174 |

| 3x0.75 | 0.6 | 0.8 | 7.6 | 68 |

| 3x1.0 | 0.6 | 0.8 | 8.0 | 79 |

| 3x1.5 | 0.7 | 0.9 | 9.4 | 111 |

| 3x2.5 | 0.8 | 1.1 | 11.4 | 169 |

| 3x4 | 0.8 | 1.2 | 13.1 | 233 |

| 4x0.75 | 0.6 | 0.8 | 8.3 | 84 |

| 4x1.0 | 0.6 | 0.9 | 9.0 | 101 |

| 4x1.5 | 0.7 | 1.0 | 10.5 | 142 |

| 4x2.5 | 0.8 | 1.1 | 12.5 | 211 |

| 4x4 | 0.8 | 1.2 | 14.3 | 292 |

| 5x0.75 | 0.6 | 0.9 | 9.3 | 106 |

| 5x1.0 | 0.6 | 0.9 | 9.8 | 123 |

| 5x1.5 | 0.7 | 1.1 | 11.6 | 176 |

| 5x2.5 | 0.8 | 1.2 | 13.9 | 262 |

| 5x4 | 0.8 | 1.4 | 16.1 | 369 |

Electrical Properties

Current-Carrying Capacities (Amp) according to BS7671:2008 table 4F3A

| Conductor cross-sectional area | Single-phase a.c. | Three-phase a.c. |

| mm2 | A | A |

| 0.5 | 3 | 3 |

| 0.75 | 6 | 6 |

| 1.0 | 10 | 10 |

| 1.5 | 16 | 16 |

| 2.5 | 25 | 20 |

| 4 | 32 | 25 |

Voltage Drop (Per Amp Per Meter) according to BS7671:2008 table 4F3B

| Conductor cross-sectional area | d.c. or single-phase a.c. | Three-phase a.c. |

| mm2 | mV/A/m | mV/A/m |

| 0.5 | 93 | 80 |

| 0.75 | 62 | 54 |

| 1.0 | 46 | 40 |

| 1.5 | 32 | 27 |

| 2.5 | 19 | 16 |

| 4 | 12 | 10 |

PVC SHEATH FLAME RETARDANT CABLE TO IEC60332 300/500V PVC Insulated, PVC Sheathed Power Cables (2-5 Cores)

05VV-K (CU/PVC/PVC 300/500V Class 5)

BS Code: 3182Y/3183Y/3184Y/3185Y

HAR Code: H05VV-F

| Application: | The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. |

| STANDARDS: | Basic design to BS EN 50525-2-11(formerly BS 6500) |

| Fire Performance: | Flame Retardance (Single Vertical Wire Test) EN 60332-1-2 |

| Voltage Rating: | 300/500V |

| Conductor | Flexible copper wire according to EN 60228 class 5. |

| Insulation | PVC type TI 2 according to EN 50363-3. |

| Filling | For circular cable having two cores, the space between the cores shall be filled either by separate fillers or by the sheath filling the interstices. For circular cables with three, four or five cores, a centre filler may be used. |

| Outer Sheath | PVC type TM 2 according to EN 50363-4-1. A tape may be applied around the core assembly before application of the sheath. |

| Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour

Cables and cords with a green-and-yellow cores

| No. of cores | Colour of coresb | ||||

| Protective | Live | ||||

| 3 Cores | Yellow/Green | Blue | Brown | ||

| 4 Cores | Yellow/Green | - | Brown | Black | Grey |

| 4 Coresa | Yellow/Green | Blue | Brown | Black | |

| 5 Cores | Yellow/Green | Blue | Brown | Black | Grey |

| a For certain applications only. | |||||

| b In this table an uninsulated concentric conductor, such as a metallic sheath, armour or screen wire, is not regarded as a core. A concentric conductor is identified by its position and, therefore, need not be identified by colour. | |||||

Cables and cords without a green-and-yellow cores

| No. of cores | Colour of coresb | ||||

| 2 Cores | Blue | Brown | |||

| 3 Cores | - | Brown | Black | Grey | |

| 3 Coresa | Blue | Brown | Black | ||

| 4 Cores | Blue | Brown | Black | Grey | |

| 5 Cores | Blue | Brown | Black | Grey | Black |

| a For certain applications only. | |||||

| b In this table an uninsulated concentric conductor, such as a metallic sheath, armour or screen wire, is not regarded as a core. A concentric conductor is identified by its position and, therefore, need not be identified by colour. | |||||

Sheath Colour: Black (other colors upon request)

Physical And Thermal Properties

| Maximum temperature range during operation (PVC) | 60°C |

| Maximum short circuit temperature (5 Seconds) | 150°C |

| Minimum bending radius | Up to 12mm²: 3 x overall diameter |

| Above 12mm²: 4 x overall diameter |

Construction Parameters

| No. of Core X Cross Section | ||||

| Nominal Insulation Thickness | Nominal Sheath Thickness | Maximum Overall Diameter | Approx. Weight | |

| Noxmm2 | mm | mm | mm | kg/km |

| 2x0.75 | 0.6 | 0.8 | 7.2 | 57 |

| 2x1.0 | 0.6 | 0.8 | 7.5 | 65 |

| 2x1.5 | 0.7 | 0.8 | 8.6 | 87 |

| 2x2.5 | 0.8 | 1.0 | 10.6 | 134 |

| 2x4 | 0.8 | 1.1 | 12.1 | 174 |

| 3x0.75 | 0.6 | 0.8 | 7.6 | 68 |

| 3x1.0 | 0.6 | 0.8 | 8.0 | 79 |

| 3x1.5 | 0.7 | 0.9 | 9.4 | 111 |

| 3x2.5 | 0.8 | 1.1 | 11.4 | 169 |

| 3x4 | 0.8 | 1.2 | 13.1 | 233 |

| 4x0.75 | 0.6 | 0.8 | 8.3 | 84 |

| 4x1.0 | 0.6 | 0.9 | 9.0 | 101 |

| 4x1.5 | 0.7 | 1.0 | 10.5 | 142 |

| 4x2.5 | 0.8 | 1.1 | 12.5 | 211 |

| 4x4 | 0.8 | 1.2 | 14.3 | 292 |

| 5x0.75 | 0.6 | 0.9 | 9.3 | 106 |

| 5x1.0 | 0.6 | 0.9 | 9.8 | 123 |

| 5x1.5 | 0.7 | 1.1 | 11.6 | 176 |

| 5x2.5 | 0.8 | 1.2 | 13.9 | 262 |

| 5x4 | 0.8 | 1.4 | 16.1 | 369 |

Electrical Properties

Current-Carrying Capacities (Amp) according to BS7671:2008 table 4F3A

| Conductor cross-sectional area | Single-phase a.c. | Three-phase a.c. |

| mm2 | A | A |

| 0.5 | 3 | 3 |

| 0.75 | 6 | 6 |

| 1.0 | 10 | 10 |

| 1.5 | 16 | 16 |

| 2.5 | 25 | 20 |

| 4 | 32 | 25 |

Voltage Drop (Per Amp Per Meter) according to BS7671:2008 table 4F3B

| Conductor cross-sectional area | d.c. or single-phase a.c. | Three-phase a.c. |

| mm2 | mV/A/m | mV/A/m |

| 0.5 | 93 | 80 |

| 0.75 | 62 | 54 |

| 1.0 | 46 | 40 |

| 1.5 | 32 | 27 |

| 2.5 | 19 | 16 |

| 4 | 12 | 10 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.