NSSHCGEOEU 0.6/1kV Coal Cutter Cable (High Tensile Stress) VDE 0250 Part 812

| Availability: | |

|---|---|

| Quantity: | |

NSSHCGEOEU 0.6/1kV Coal Cutter Cable (High Tensile Stress) VDE 0250 Part 812

| Applications | These cables are used for the connection of mobile machines under extremelyhigh mechanical loads, predominantly in miningsituations, e.g. for coal-cutting machines, also can beoperated via guide pulleys (cable cars) or used as areeling cable (LHD), suitable for extreme bending loads, high tensile stress,and impact and crushing loads. |

| Standards | VDE 0250 Part 812 |

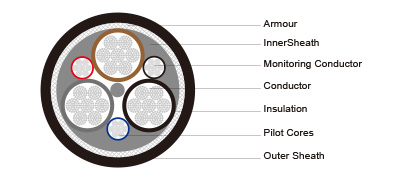

| Construction | |

| Conductors | Flexible stranded tinned copper conductor. |

| Insulation | Heatresistant3GI3 rubber based on EPR. |

| Outer Conductor Layer | Easy strippable outer conductive layer. |

| Pilot Cores | Copper and steel conductor capable ofexpansion and compression with 3GI3 EPRrubber insulation. |

| Monitoring Conductor | Copper and steel conductorcapable of expansion and compression covert with semiconductive rubber compound. |

| InnerSheath | Rubber type GM1b. |

| Armour/Earth Conductor | Concentric earth conductor as tensile-stress-resistant braided armour of combined copper-steel wires. |

| Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×16/16KON+2ST+UEL | 38.5 | 41.5 | 2430 |

3×25/16KON+2ST+UEL | 41.0 | 44.5 | 3050 |

3×35/16KON+2ST+UEL | 44.5 | 48.0 | 3620 |

3×50/25KON+2ST+UEL | 50.0 | 54.0 | 4810 |

3×70/35KON+2ST+UEL | 54.5 | 58.5 | 5890 |

3×95/50KON+2ST+UEL | 62.5 | 66.5 | 7800 |

3×35/16KON+3ST+3UEL | 44.5 | 48.0 | 3860 |

3×50/25KON+3ST+3UEL | 50.0 | 54.0 | 5050 |

3×70/35KON+3ST+3UEL | 54.5 | 58.5 | 6000 |

3×95/50KON+3ST+3UEL | 62.5 | 66.5 | 8050 |

3×120/70KON+3ST+3UEL | 67.5 | 72.0 | 9380 |

3×150/70KON+3ST+3UEL | 74.5 | 79.0 | 11120 |

NSSHCGEOEU 0.6/1kV Coal Cutter Cable (High Tensile Stress) VDE 0250 Part 812

| Applications | These cables are used for the connection of mobile machines under extremelyhigh mechanical loads, predominantly in miningsituations, e.g. for coal-cutting machines, also can beoperated via guide pulleys (cable cars) or used as areeling cable (LHD), suitable for extreme bending loads, high tensile stress,and impact and crushing loads. |

| Standards | VDE 0250 Part 812 |

| Construction | |

| Conductors | Flexible stranded tinned copper conductor. |

| Insulation | Heatresistant3GI3 rubber based on EPR. |

| Outer Conductor Layer | Easy strippable outer conductive layer. |

| Pilot Cores | Copper and steel conductor capable ofexpansion and compression with 3GI3 EPRrubber insulation. |

| Monitoring Conductor | Copper and steel conductorcapable of expansion and compression covert with semiconductive rubber compound. |

| InnerSheath | Rubber type GM1b. |

| Armour/Earth Conductor | Concentric earth conductor as tensile-stress-resistant braided armour of combined copper-steel wires. |

| Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×16/16KON+2ST+UEL | 38.5 | 41.5 | 2430 |

3×25/16KON+2ST+UEL | 41.0 | 44.5 | 3050 |

3×35/16KON+2ST+UEL | 44.5 | 48.0 | 3620 |

3×50/25KON+2ST+UEL | 50.0 | 54.0 | 4810 |

3×70/35KON+2ST+UEL | 54.5 | 58.5 | 5890 |

3×95/50KON+2ST+UEL | 62.5 | 66.5 | 7800 |

3×35/16KON+3ST+3UEL | 44.5 | 48.0 | 3860 |

3×50/25KON+3ST+3UEL | 50.0 | 54.0 | 5050 |

3×70/35KON+3ST+3UEL | 54.5 | 58.5 | 6000 |

3×95/50KON+3ST+3UEL | 62.5 | 66.5 | 8050 |

3×120/70KON+3ST+3UEL | 67.5 | 72.0 | 9380 |

3×150/70KON+3ST+3UEL | 74.5 | 79.0 | 11120 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.