LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332 600/1000V LSZH Sheathed, Armoured ((multicore)

| Availability: | |

|---|---|

| Quantity: | |

LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332 600/1000V LSZH Sheathed, Armoured ((multicore)

| Application: | This range of screened cables drastically reduce interferences from electrical noise, especially in Variable Speed Drive (VSD) applications and are manufactured with fixed conductors. |

| Standard: | Basic design to IEC 60502-1; BS 6724 |

FIRE PERFORMANCE

| Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

| Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

| Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

| No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

| minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

| No Toxic gases | NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

600/1000V

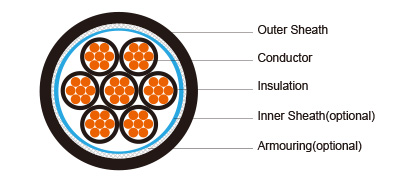

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Extruded cross-linked XLPE compound.

Inner Sheath(optional): LSZH Compound

Armouring(optional): Galvanized Steel Wire

Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

COLOUR CODE

Insulation colour as per bs7671

| with earth conductor | without earth conductor | |

| 2Cores | - | Brown,Blue |

| 3Cores | Yellow/Green,Brown,Blue | Brown,Gray,Black |

| 4Cores | Yellow/Green,Brown,Gray,Black | Brown,Gray,Black,Blue |

| 5Cores | Yellow/Green,Brown,Gray,Black,Blue | Brown,Gray,Black,Blue,Black |

| above 5 Cores | Yellow/Green,Black Numbered | Black Numbered |

sheath colour: Black

Physical AND THERMAL PROPERTIES

Temperature range during operation: Max.90°C for XLPE

250°C in short-circuit for 5s max.

Minimum bending radius: 8 x Overall Diameter (unarmoured cable)

10 x Overall Diameter (armoured cable)

CONSTRUCTION PARAMETERS

| Conductor | ||||||||

| No. of Core X Cross Section | No./ Nominal Diameter Of Strands | Nominal Insulation Thickness | ||||||

| Unarmoured | Armoured | |||||||

| Nominal Overall Diameter | Approx. Weight | Diameter Under Armour | Armour Wire Diameter | Nominal Overall Diameter | Approx. Weight | |||

| mm² | No./mm | mm | mm | kg/km | mm | mm | mm | kg/km |

| 5x1.5 | 7/0.53 | 0.7 | 11.3 | 184 | 9.9 | 0.9 | 14.5 | 402 |

| 7x1.5 | 7/0.53 | 0.7 | 12.4 | 225 | 11.2 | 0.9 | 16.0 | 490 |

| 10x1.5 | 7/0.53 | 0.7 | 15.6 | 325 | 14.3 | 1.25 | 20.0 | 761 |

| 12x1.5 | 7/0.53 | 0.7 | 16.2 | 370 | 14.8 | 1.25 | 20.5 | 827 |

| 19x1.5 | 7/0.53 | 0.7 | 19.0 | 516 | 17.4 | 1.6 | 24.0 | 1186 |

| 27x1.5 | 7/0.53 | 0.7 | 22.7 | 712 | 21.3 | 1.6 | 28.1 | 1537 |

| 37x1.5 | 7/0.53 | 0.7 | 25.5 | 941 | 23.9 | 1.6 | 30.7 | 1856 |

| 48x1.5 | 7/0.53 | 0.7 | 29.0 | 1186 | 27.5 | 1.6 | 34.6 | 2276 |

| 5x2.5 | 7/0.67 | 0.7 | 12.8 | 237 | 11.2 | 0.9 | 15.8 | 496 |

| 7x2.5 | 7/0.67 | 0.7 | 13.8 | 303 | 12.4 | 0.9 | 17.2 | 602 |

| 10x2.5 | 7/0.67 | 0.7 | 17.5 | 426 | 15.9 | 1.25 | 21.8 | 943 |

| 12x2.5 | 7/0.67 | 0.7 | 18.1 | 489 | 16.5 | 1.25 | 22.4 | 1020 |

| 19x2.5 | 7/0.67 | 0.7 | 21.3 | 725 | 19.9 | 1.6 | 26.7 | 1498 |

| 27x2.5 | 7/0.67 | 0.7 | 25.5 | 1004 | 23.9 | 1.6 | 30.9 | 1933 |

| 37x2.5 | 7/0.67 | 0.7 | 28.7 | 1334 | 26.9 | 1.6 | 33.9 | 2372 |

| 48x2.5 | 7/0.67 | 0.7 | 32.9 | 1706 | 31.3 | 2.0 | 39.6 | 3252 |

| 5x4 | 7/0.85 | 0.7 | 14.2 | 324 | 12.6 | 1.25 | 18.2 | 712 |

| 7x4 | 7/0.85 | 0.7 | 15.5 | 422 | 14.1 | 1.25 | 19.8 | 871 |

| 10x4 | 7/0.85 | 0.7 | 19.7 | 597 | 18.5 | 1.25 | 24.4 | 1213 |

| 12x4 | 7/0.85 | 0.7 | 20.3 | 690 | 19.1 | 1.6 | 25.7 | 1462 |

| 19x4 | 7/0.85 | 0.7 | 24.0 | 1037 | 22.6 | 1.6 | 29.4 | 1931 |

| 27x4 | 7/0.85 | 0.7 | 28.8 | 1445 | 27.2 | 1.6 | 34.4 | 2532 |

| 37x4 | 7/0.85 | 0.7 | 32.5 | 1932 | 31.1 | 2.0 | 39.3 | 3448 |

| 48x4 | 7/0.85 | 0.7 | 37.3 | 2479 | 35.7 | 2.0 | 44.2 | 4273 |

Note : Other conductor sizes & core confi gurations are available upon request.

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Unarmoured Current-Carrying Capacities (Amp)

| Conductor cross- sectional area | Reference method 4 (enclosed in conduit in thermally insulating wall etc) | Reference method 3 (enclosed in conduit on a wall or in trunking etc) | Reference method 1 (clipped direct) | Reference method 11 (on a perforated cable tray, horizontal or vertical) | Reference method 12 (free air) | ||||||

| Horizontal flat spaced | Vertical flat spaced | Trefoil | |||||||||

| 2 cables, single- phase a.c. or d.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single- phase a.c. or d.c | 3 or 4 cables, 3-phase a.c. | 2 cables, single- phase a.c. or d.c. flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single- phase a.c. or d.c. or flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single- phase a.c. or d.c. or 3 c ables three phase | 2 cables, single- phase a.c. or d.c. or 3 cables three phase | 3 cables, trefoil 3-phase a.c. | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| mm² | A | A | A | A | A | A | A | A | A | A | A |

| 1.5 | 18 | 17 | 22 | 19 | 25 | 23 | - | - | - | - | - |

| 2.5 | 24 | 23 | 30 | 26 | 34 | 31 | - | - | - | - | - |

| 4 | 33 | 30 | 40 | 35 | 46 | 41 | - | - | - | - | - |

Voltage Drop (Per Amp Per Meter)

| Size of conductor | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | |||

| Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1 and 11 (clipped direct or on trays touching) | Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1, 11 and 12 (in trefoil) | Ref. Methods 1 and 11(Flat and touching) | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

| 1.5 | 31 | 31 | 27 | 27 | 27 | 27 |

| 2.5 | 19 | 19 | 16 | 16 | 16 | 16 |

| 4 | 33 | 12 | 10 | 10 | 10 | 10 |

Armoured Current-Carrying Capacities (Amp)

| Conductor crosssectional area | Reference Method 1 (clipped direct) | Reference Method 11 (on a perforated horizontal cable trayor Reference Method 13 [free air] ) | In single-way ducts | Laid direct in ground | ||||

| one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| mm² | A | A | A | A | A | A | A | A |

| 1.5 | 27 | 23 | 29 | 25 | - | 23 | - | 28 |

| 2.5 | 36 | 31 | 39 | 33 | - | 30 | - | 36 |

| 4 | 49 | 42 | 52 | 44 | - | 40 | - | 48 |

Voltage Drop (Per Amp Per Meter)

| Conductor cross-sectional area | 2-core cable d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single- phase a.c. | 3 or 4 cables, 3-phase a.c. |

| In ducts or in ground | In ducts or in ground | ||||

| 1 | 2 | 3 | 4 | 5 | 6 |

| mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

| 1.5 | 31.0 | 31.0 | 27.0 | 31.0 | 25.0 |

| 2.5 | 19.0 | 19.0 | 16.0 | 19.0 | 15.0 |

| 4 | 12.0 | 12.0 | 10.0 | 12.0 | 9.7 |

LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332 600/1000V LSZH Sheathed, Armoured ((multicore)

| Application: | This range of screened cables drastically reduce interferences from electrical noise, especially in Variable Speed Drive (VSD) applications and are manufactured with fixed conductors. |

| Standard: | Basic design to IEC 60502-1; BS 6724 |

FIRE PERFORMANCE

| Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

| Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

| Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

| No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

| minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

| No Toxic gases | NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Extruded cross-linked XLPE compound.

Inner Sheath(optional): LSZH Compound

Armouring(optional): Galvanized Steel Wire

Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

COLOUR CODE

Insulation colour as per bs7671

| with earth conductor | without earth conductor | |

| 2Cores | - | Brown,Blue |

| 3Cores | Yellow/Green,Brown,Blue | Brown,Gray,Black |

| 4Cores | Yellow/Green,Brown,Gray,Black | Brown,Gray,Black,Blue |

| 5Cores | Yellow/Green,Brown,Gray,Black,Blue | Brown,Gray,Black,Blue,Black |

| above 5 Cores | Yellow/Green,Black Numbered | Black Numbered |

sheath colour: Black

Physical AND THERMAL PROPERTIES

Temperature range during operation: Max.90°C for XLPE

250°C in short-circuit for 5s max.

Minimum bending radius: 8 x Overall Diameter (unarmoured cable)

10 x Overall Diameter (armoured cable)

CONSTRUCTION PARAMETERS

| Conductor | ||||||||

| No. of Core X Cross Section | No./ Nominal Diameter Of Strands | Nominal Insulation Thickness | ||||||

| Unarmoured | Armoured | |||||||

| Nominal Overall Diameter | Approx. Weight | Diameter Under Armour | Armour Wire Diameter | Nominal Overall Diameter | Approx. Weight | |||

| mm² | No./mm | mm | mm | kg/km | mm | mm | mm | kg/km |

| 5x1.5 | 7/0.53 | 0.7 | 11.3 | 184 | 9.9 | 0.9 | 14.5 | 402 |

| 7x1.5 | 7/0.53 | 0.7 | 12.4 | 225 | 11.2 | 0.9 | 16.0 | 490 |

| 10x1.5 | 7/0.53 | 0.7 | 15.6 | 325 | 14.3 | 1.25 | 20.0 | 761 |

| 12x1.5 | 7/0.53 | 0.7 | 16.2 | 370 | 14.8 | 1.25 | 20.5 | 827 |

| 19x1.5 | 7/0.53 | 0.7 | 19.0 | 516 | 17.4 | 1.6 | 24.0 | 1186 |

| 27x1.5 | 7/0.53 | 0.7 | 22.7 | 712 | 21.3 | 1.6 | 28.1 | 1537 |

| 37x1.5 | 7/0.53 | 0.7 | 25.5 | 941 | 23.9 | 1.6 | 30.7 | 1856 |

| 48x1.5 | 7/0.53 | 0.7 | 29.0 | 1186 | 27.5 | 1.6 | 34.6 | 2276 |

| 5x2.5 | 7/0.67 | 0.7 | 12.8 | 237 | 11.2 | 0.9 | 15.8 | 496 |

| 7x2.5 | 7/0.67 | 0.7 | 13.8 | 303 | 12.4 | 0.9 | 17.2 | 602 |

| 10x2.5 | 7/0.67 | 0.7 | 17.5 | 426 | 15.9 | 1.25 | 21.8 | 943 |

| 12x2.5 | 7/0.67 | 0.7 | 18.1 | 489 | 16.5 | 1.25 | 22.4 | 1020 |

| 19x2.5 | 7/0.67 | 0.7 | 21.3 | 725 | 19.9 | 1.6 | 26.7 | 1498 |

| 27x2.5 | 7/0.67 | 0.7 | 25.5 | 1004 | 23.9 | 1.6 | 30.9 | 1933 |

| 37x2.5 | 7/0.67 | 0.7 | 28.7 | 1334 | 26.9 | 1.6 | 33.9 | 2372 |

| 48x2.5 | 7/0.67 | 0.7 | 32.9 | 1706 | 31.3 | 2.0 | 39.6 | 3252 |

| 5x4 | 7/0.85 | 0.7 | 14.2 | 324 | 12.6 | 1.25 | 18.2 | 712 |

| 7x4 | 7/0.85 | 0.7 | 15.5 | 422 | 14.1 | 1.25 | 19.8 | 871 |

| 10x4 | 7/0.85 | 0.7 | 19.7 | 597 | 18.5 | 1.25 | 24.4 | 1213 |

| 12x4 | 7/0.85 | 0.7 | 20.3 | 690 | 19.1 | 1.6 | 25.7 | 1462 |

| 19x4 | 7/0.85 | 0.7 | 24.0 | 1037 | 22.6 | 1.6 | 29.4 | 1931 |

| 27x4 | 7/0.85 | 0.7 | 28.8 | 1445 | 27.2 | 1.6 | 34.4 | 2532 |

| 37x4 | 7/0.85 | 0.7 | 32.5 | 1932 | 31.1 | 2.0 | 39.3 | 3448 |

| 48x4 | 7/0.85 | 0.7 | 37.3 | 2479 | 35.7 | 2.0 | 44.2 | 4273 |

Note : Other conductor sizes & core confi gurations are available upon request.

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Unarmoured Current-Carrying Capacities (Amp)

| Conductor cross- sectional area | Reference method 4 (enclosed in conduit in thermally insulating wall etc) | Reference method 3 (enclosed in conduit on a wall or in trunking etc) | Reference method 1 (clipped direct) | Reference method 11 (on a perforated cable tray, horizontal or vertical) | Reference method 12 (free air) | ||||||

| Horizontal flat spaced | Vertical flat spaced | Trefoil | |||||||||

| 2 cables, single- phase a.c. or d.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single- phase a.c. or d.c | 3 or 4 cables, 3-phase a.c. | 2 cables, single- phase a.c. or d.c. flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single- phase a.c. or d.c. or flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single- phase a.c. or d.c. or 3 c ables three phase | 2 cables, single- phase a.c. or d.c. or 3 cables three phase | 3 cables, trefoil 3-phase a.c. | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| mm² | A | A | A | A | A | A | A | A | A | A | A |

| 1.5 | 18 | 17 | 22 | 19 | 25 | 23 | - | - | - | - | - |

| 2.5 | 24 | 23 | 30 | 26 | 34 | 31 | - | - | - | - | - |

| 4 | 33 | 30 | 40 | 35 | 46 | 41 | - | - | - | - | - |

Voltage Drop (Per Amp Per Meter)

| Size of conductor | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | |||

| Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1 and 11 (clipped direct or on trays touching) | Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1, 11 and 12 (in trefoil) | Ref. Methods 1 and 11(Flat and touching) | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

| 1.5 | 31 | 31 | 27 | 27 | 27 | 27 |

| 2.5 | 19 | 19 | 16 | 16 | 16 | 16 |

| 4 | 33 | 12 | 10 | 10 | 10 | 10 |

Armoured Current-Carrying Capacities (Amp)

| Conductor crosssectional area | Reference Method 1 (clipped direct) | Reference Method 11 (on a perforated horizontal cable trayor Reference Method 13 [free air] ) | In single-way ducts | Laid direct in ground | ||||

| one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | one 2-core cable single phase a.c. or d.c. | one 3-core or 4-core cable 3-phase a.c. | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| mm² | A | A | A | A | A | A | A | A |

| 1.5 | 27 | 23 | 29 | 25 | - | 23 | - | 28 |

| 2.5 | 36 | 31 | 39 | 33 | - | 30 | - | 36 |

| 4 | 49 | 42 | 52 | 44 | - | 40 | - | 48 |

Voltage Drop (Per Amp Per Meter)

| Conductor cross-sectional area | 2-core cable d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single- phase a.c. | 3 or 4 cables, 3-phase a.c. |

| In ducts or in ground | In ducts or in ground | ||||

| 1 | 2 | 3 | 4 | 5 | 6 |

| mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

| 1.5 | 31.0 | 31.0 | 27.0 | 31.0 | 25.0 |

| 2.5 | 19.0 | 19.0 | 16.0 | 19.0 | 15.0 |

| 4 | 12.0 | 12.0 | 10.0 | 12.0 | 9.7 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.