You are here: Home / Products / Wire and Cables / INDUSTRIAL CABLES / Harmonized Standard Industrial Cables H05V-U/H07V-U

Harmonized Standard Industrial Cables H05V-U/H07V-U

Harmonized Standard Industrial Cables H05V-U/H07V-U

| Application and Description | H05 V-U/(H)05 V-U These insulated wires are determined for tde installation to tde inside of apparatus as well as for tde protective laying to tde lightings, in dry rooms, in production facilities, switch and distributor boards, in tubes, under and surface mounting of plasters. H07 V-U/(H)07 V-U These insulated wires are suitable for laying tubes, under and surface mounting of plasters and also in closed installation conduits. These are not allowed to install for direct laying in cable trays, channels or tanks. These types are permitted for tde inner wiring of equipment, distributor and switchboards and also for protective laying to tde lightings witd a nominal voltage up to 1000 V alternating current or up to 750 V direct current against ground. |

| Standard and Approval | HD 21.3 S3, VDE-0281 Part-3, CEI20-20/3, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant |

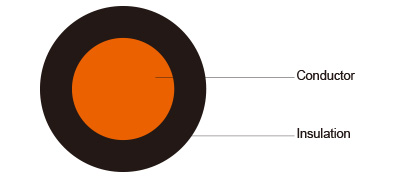

| Cable Construction | 1- Solid bare copper single wire - Solid to DIN VDE 0295 cl-1 and IEC 60228 cl-1 2- Special PVC TI1 core insulation - Cores to VDE-0293 colors on chart - H05V-U (20, 18 & 17 AWG) - H07V-U (16 AWG and Larger) |

| Technical Characteristics | - Working voltage: 300/500v (H05V-U) - Working voltage: 450/750v (H07V-U) - Test voltage: 2000V(H05V-U)/2500V (H07V-U) - Flexing bending radius: 15 x Ø - Static bending radius: 15 x Ø - Flexing temperature: -5º C to +70º C - Static temperature: -30º C to +90º C - Short circuit temperature: +160º C - Flame retardant: IEC 60332.1 - Insulation resistance: 10 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² | NOMINAL THICKNESS OF INSULATION MM | NOMINAL OVERALL DIAMETER MM | NOMINAL COPPER WEIGHTKG/KM | NOMINAL WEIGHTKG/KM |

20 | 1 x 0.5 | 0.6 | 2.1 | 4.8 | 9 |

18 | 1 x 0.75 | 0.6 | 2.2 | 7.2 | 11 |

17 | 1 x 1 | 0.6 | 2.4 | 9.6 | 14 |

16 | 1 x 1.5 | 0.7 | 2.9 | 14.4 | 21 |

14 | 1 x 2.5 | 0.8 | 3.5 | 24.0 | 33 |

12 | 1 x 4 | 0.8 | 3.9 | 38.0 | 49 |

10 | 1 x 6 | 0.8 | 4.5 | 58.0 | 69 |

8 | 1 x 10 | 1.0 | 5.7 | 96.0 | 115 |

<template class="visibility">

Harmonized Standard Industrial Cables H05V-U/H07V-U

| Application and Description | H05 V-U/(H)05 V-U These insulated wires are determined for tde installation to tde inside of apparatus as well as for tde protective laying to tde lightings, in dry rooms, in production facilities, switch and distributor boards, in tubes, under and surface mounting of plasters. H07 V-U/(H)07 V-U These insulated wires are suitable for laying tubes, under and surface mounting of plasters and also in closed installation conduits. These are not allowed to install for direct laying in cable trays, channels or tanks. These types are permitted for tde inner wiring of equipment, distributor and switchboards and also for protective laying to tde lightings witd a nominal voltage up to 1000 V alternating current or up to 750 V direct current against ground. |

| Standard and Approval | HD 21.3 S3, VDE-0281 Part-3, CEI20-20/3, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant |

| Cable Construction | 1- Solid bare copper single wire - Solid to DIN VDE 0295 cl-1 and IEC 60228 cl-1 2- Special PVC TI1 core insulation - Cores to VDE-0293 colors on chart - H05V-U (20, 18 & 17 AWG) - H07V-U (16 AWG and Larger) |

| Technical Characteristics | - Working voltage: 300/500v (H05V-U) - Working voltage: 450/750v (H07V-U) - Test voltage: 2000V(H05V-U)/2500V (H07V-U) - Flexing bending radius: 15 x Ø - Static bending radius: 15 x Ø - Flexing temperature: -5º C to +70º C - Static temperature: -30º C to +90º C - Short circuit temperature: +160º C - Flame retardant: IEC 60332.1 - Insulation resistance: 10 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² | NOMINAL THICKNESS OF INSULATION MM | NOMINAL OVERALL DIAMETER MM | NOMINAL COPPER WEIGHTKG/KM | NOMINAL WEIGHTKG/KM |

20 | 1 x 0.5 | 0.6 | 2.1 | 4.8 | 9 |

18 | 1 x 0.75 | 0.6 | 2.2 | 7.2 | 11 |

17 | 1 x 1 | 0.6 | 2.4 | 9.6 | 14 |

16 | 1 x 1.5 | 0.7 | 2.9 | 14.4 | 21 |

14 | 1 x 2.5 | 0.8 | 3.5 | 24.0 | 33 |

12 | 1 x 4 | 0.8 | 3.9 | 38.0 | 49 |

10 | 1 x 6 | 0.8 | 4.5 | 58.0 | 69 |

8 | 1 x 10 | 1.0 | 5.7 | 96.0 | 115 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Add : Youth Enterprenership Park No. 1313, Shuangshan Street, Zhangqiu District, Jinan City, Shandong Province.

Tel : +8613964006035

E-mail : jnhjkd@163.com

Tel : +8613964006035

E-mail : jnhjkd@163.com

hjmouldtech@gmail.com

WhatsApp:+8618396877830

WhatsApp:+8618396877830

An important note.

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.