Harmonized Code Industrial Cables H07ZZ-F

Harmonized Code Industrial Cables H07ZZ-F

| Application and Description | These LSZH cables are flexible, mainly used for mobile service, suitable for installations where is required low smoke and halogen free fumes under fire conditions. Suitable for installations where tde cable must witdstand medium mechanical stress, for machines in industrial and agricultural workshops, for motors and some transportable machines , for wind mills and for agricultural exploitations. |

| Standard and Approval | HD22.13 S1 & A1 VDE-0282 Part-13 CEI 20-19 p.13 IEC 60245-4 IEC 60754 EN 61034 CE low voltage directive 73/23/EEC & 93/68/EEC ROHS compliant |

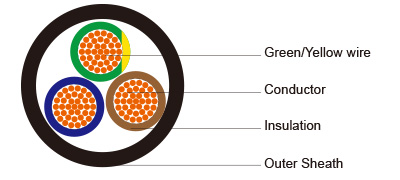

| Cable Construction | 1 Fine bare copper strands Strands to VDE-0295 Class-5, IEC 60228 Class-5 2 Halogen free rubber compound EI 8 acc. to EN 50363-5 Color code to VDE-0293-308 3 Black halogen free rubber compound EM8 jacket |

| Technical Characteristics | FLEXING VOLTAGE: 450/750 volts FIXED VOLTAGE: 600/1000 volts TEST VOLTAGE: 2500 volts FLEXING BENDING RADIUS: 6 x Ø FIXED BENDING RADIUS: 4 x Ø FLEXING TEMPERATURE: -5 ºC to +70 ºC FIXED TEMPERATURE: -40 ºC to +70 ºC SHORT CIRCUIT TEMPERATURE: +250 ºC FLAME RETARDANT: IEC 60332.3 C1, NF C 32-070 INSULATION RESISTANCE: 20 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

# X MM² | MM | MM | MM(MIN-MAX) | KG/KM | KG/KM | |

17(32/32) | 2 x 1 | 0.8 | 1.3 | 7.7-10 | 19 | 96 |

17(32/32) | 3 x 1 | 0.8 | 1.4 | 8.3-10.7 | 29 | 116 |

17(32/32) | 4 x 1 | 0.8 | 1.5 | 9.2-11.9 | 38 | 143 |

17(32/32) | 5 x 1 | 0.8 | 1.6 | 10.2-13.1 | 46 | 171 |

16(30/30) | 1 x 1.5 | 0.8 | 1.4 | 5.7-7.1 | 14.4 | 58.5 |

16(30/30) | 2 x 1.5 | 0.8 | 1.5 | 8.5-11.0 | 29 | 120 |

16(30/30) | 3 x 1.5 | 0.8 | 1.6 | 9.2-11.9 | 43 | 146 |

16(30/30) | 4 x 1.5 | 0.8 | 1.7 | 10.2-13.1 | 58 | 177 |

16(30/30) | 5 x 1.5 | 0.8 | 1.8 | 11.2-14.4 | 72 | 216 |

16(30/30) | 7 x 1.5 | 0.8 | 2.5 | 14.5-17.5 | 101 | 305 |

16(30/30) | 12 x 1.5 | 0.8 | 2.9 | 17.6-22.4 | 173 | 500 |

16(30/30) | 14 x 1.5 | 0.8 | 3.1 | 18.8-21.3 | 196 | 573 |

16(30/30) | 18 x 1.5 | 0.8 | 3.2 | 20.7-26.3 | 274 | 755 |

16(30/30) | 24 x 1.5 | 0.8 | 3.5 | 24.3-30.7 | 346 | 941 |

16(30/30) | 36 x 1.5 | 0.8 | 3.8 | 27.8-35.2 | 507 | 1305 |

14(50/30) | 1 x 2.5 | 0.9 | 1.4 | 6.3-7.9 | 24 | 72 |

14(50/30) | 2 x 2.5 | 0.9 | 1.7 | 10.2-13.1 | 48 | 173 |

14(50/30) | 3 x 2.5 | 0.9 | 1.8 | 10.9-14.0 | 72 | 213 |

14(50/30) | 4 x 2.5 | 0.9 | 1.9 | 12.1-15.5 | 96 | 237 |

14(50/30) | 5 x 2.5 | 0.9 | 2.0 | 13.3-17.0 | 120 | 318 |

14(50/30) | 7 x 2.5 | 0.9 | 2.7 | 16.5-20.0 | 168 | 450 |

14(50/30) | 12 x 2.5 | 0.9 | 3.1 | 20.6-26.2 | 288 | 729 |

14(50/30) | 14 x 2.5 | 0.9 | 3.2 | 22.2-25.0 | 337 | 866 |

14(50/30) | 18 x 2.5 | 0.9 | 3.5 | 24.4-30.9 | 456 | 1086 |

14(50/30) | 24 x 2.5 | 0.9 | 3.9 | 28.8-36.4 | 576 | 1332 |

14(50/30) | 36 x 2.5 | 0.9 | 4.3 | 33.2-41.8 | 1335 | 1961 |

12(56/28) | 1 x 4 | 1 | 1.5 | 7.2-9.0 | 38 | 101 |

12(56/28) | 3 x 4 | 1 | 1.9 | 12.7-16.2 | 115 | 293 |

12(56/28) | 4 x 4 | 1 | 2.0 | 14.0-17.9 | 154 | 368 |

12(56/28) | 5 x 4 | 1 | 2.2 | 15.6-19.9 | 192 | 450 |

12(56/28) | 12 x 4 | 1 | 3.5 | 24.2-30.9 | 464 | 1049 |

Harmonized Code Industrial Cables H07ZZ-F

| Application and Description | These LSZH cables are flexible, mainly used for mobile service, suitable for installations where is required low smoke and halogen free fumes under fire conditions. Suitable for installations where tde cable must witdstand medium mechanical stress, for machines in industrial and agricultural workshops, for motors and some transportable machines , for wind mills and for agricultural exploitations. |

| Standard and Approval | HD22.13 S1 & A1 VDE-0282 Part-13 CEI 20-19 p.13 IEC 60245-4 IEC 60754 EN 61034 CE low voltage directive 73/23/EEC & 93/68/EEC ROHS compliant |

| Cable Construction | 1 Fine bare copper strands Strands to VDE-0295 Class-5, IEC 60228 Class-5 2 Halogen free rubber compound EI 8 acc. to EN 50363-5 Color code to VDE-0293-308 3 Black halogen free rubber compound EM8 jacket |

| Technical Characteristics | FLEXING VOLTAGE: 450/750 volts FIXED VOLTAGE: 600/1000 volts TEST VOLTAGE: 2500 volts FLEXING BENDING RADIUS: 6 x Ø FIXED BENDING RADIUS: 4 x Ø FLEXING TEMPERATURE: -5 ºC to +70 ºC FIXED TEMPERATURE: -40 ºC to +70 ºC SHORT CIRCUIT TEMPERATURE: +250 ºC FLAME RETARDANT: IEC 60332.3 C1, NF C 32-070 INSULATION RESISTANCE: 20 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

# X MM² | MM | MM | MM(MIN-MAX) | KG/KM | KG/KM | |

17(32/32) | 2 x 1 | 0.8 | 1.3 | 7.7-10 | 19 | 96 |

17(32/32) | 3 x 1 | 0.8 | 1.4 | 8.3-10.7 | 29 | 116 |

17(32/32) | 4 x 1 | 0.8 | 1.5 | 9.2-11.9 | 38 | 143 |

17(32/32) | 5 x 1 | 0.8 | 1.6 | 10.2-13.1 | 46 | 171 |

16(30/30) | 1 x 1.5 | 0.8 | 1.4 | 5.7-7.1 | 14.4 | 58.5 |

16(30/30) | 2 x 1.5 | 0.8 | 1.5 | 8.5-11.0 | 29 | 120 |

16(30/30) | 3 x 1.5 | 0.8 | 1.6 | 9.2-11.9 | 43 | 146 |

16(30/30) | 4 x 1.5 | 0.8 | 1.7 | 10.2-13.1 | 58 | 177 |

16(30/30) | 5 x 1.5 | 0.8 | 1.8 | 11.2-14.4 | 72 | 216 |

16(30/30) | 7 x 1.5 | 0.8 | 2.5 | 14.5-17.5 | 101 | 305 |

16(30/30) | 12 x 1.5 | 0.8 | 2.9 | 17.6-22.4 | 173 | 500 |

16(30/30) | 14 x 1.5 | 0.8 | 3.1 | 18.8-21.3 | 196 | 573 |

16(30/30) | 18 x 1.5 | 0.8 | 3.2 | 20.7-26.3 | 274 | 755 |

16(30/30) | 24 x 1.5 | 0.8 | 3.5 | 24.3-30.7 | 346 | 941 |

16(30/30) | 36 x 1.5 | 0.8 | 3.8 | 27.8-35.2 | 507 | 1305 |

14(50/30) | 1 x 2.5 | 0.9 | 1.4 | 6.3-7.9 | 24 | 72 |

14(50/30) | 2 x 2.5 | 0.9 | 1.7 | 10.2-13.1 | 48 | 173 |

14(50/30) | 3 x 2.5 | 0.9 | 1.8 | 10.9-14.0 | 72 | 213 |

14(50/30) | 4 x 2.5 | 0.9 | 1.9 | 12.1-15.5 | 96 | 237 |

14(50/30) | 5 x 2.5 | 0.9 | 2.0 | 13.3-17.0 | 120 | 318 |

14(50/30) | 7 x 2.5 | 0.9 | 2.7 | 16.5-20.0 | 168 | 450 |

14(50/30) | 12 x 2.5 | 0.9 | 3.1 | 20.6-26.2 | 288 | 729 |

14(50/30) | 14 x 2.5 | 0.9 | 3.2 | 22.2-25.0 | 337 | 866 |

14(50/30) | 18 x 2.5 | 0.9 | 3.5 | 24.4-30.9 | 456 | 1086 |

14(50/30) | 24 x 2.5 | 0.9 | 3.9 | 28.8-36.4 | 576 | 1332 |

14(50/30) | 36 x 2.5 | 0.9 | 4.3 | 33.2-41.8 | 1335 | 1961 |

12(56/28) | 1 x 4 | 1 | 1.5 | 7.2-9.0 | 38 | 101 |

12(56/28) | 3 x 4 | 1 | 1.9 | 12.7-16.2 | 115 | 293 |

12(56/28) | 4 x 4 | 1 | 2.0 | 14.0-17.9 | 154 | 368 |

12(56/28) | 5 x 4 | 1 | 2.2 | 15.6-19.9 | 192 | 450 |

12(56/28) | 12 x 4 | 1 | 3.5 | 24.2-30.9 | 464 | 1049 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.