German Standard Industrial Cables LiHCH

German Standard Industrial Cables LiHCH

| Application and Description | LiHCH is for use in flexible or stationary applications under low mechanical stress with free movement without any tensile stress, loads or forced movements in dry, moist and wet conditions. Commonly used as connecting cable for signal, measuring, control, call-announcing and two-way intercom systems, clock installations, electronic weighing machines and electrical apparatus for office use. The halogenfree thermoplastic jacket is flame retardant and will give off no corrosive or toxic gases in the case of fire. Commonly installed in public buildings, laboratories, trading and transportation centers. The tinned copper braid shield offers interference-free signal and data transfers. Not permitted for outdoor use. |

| Standard and Approval | VDE 0482 part 267, VDE 0812, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant |

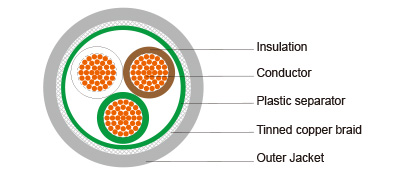

| Cable Construction | - Plain copper conductor - Stranded to DIN VDE 0295 cl. 5, IEC 60228 cl.5 - Halogen free core insulation - Color coded to DIN 47100, but without color repetition - Plastic foil separator - 85% tinned copper braid - Halogen free outer jacket |

| Technical Characteristics | - Working voltage: 350 volts - Test voltage: 1200 volts - Minimum bending radius: 5 x Ø - Flexing temperature: -5º C to +70º C - Static temperature: -40º C to +70º C - Flame retardant: IEC 60332.1-2 - Mutual Capacitance: Conductor./conductor: 120 nF/km Conductor./shield: 160 nF/km - Halogen free: DIN EN 50267/IEC 60754 - Smoke density: DIN EN50268/IEC 61034 - Insulation resistance: 20 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² | NOMINAL OVERALL DIAMETER MM | COPPER WEIGHT KG / KM | CABLE WEIGHT KG / KM |

26(18/38) | 2x0.14 | 3.9 | 8 | 21 |

26(18/38) | 3x0.14 | 4.2 | 11 | 26 |

26(18/38) | 4x014 | 4.5 | 12.5 | 28 |

26(18/38) | 5x0.14 | 4.8 | 13.5 | 33 |

26(18/38) | 6x0.14 | 5.1 | 15.5 | 37 |

26(18/38) | 7x0.14 | 5.1 | 17 | 40 |

26(18/38) | 8x0.14 | 5.5 | 19.5 | 46 |

26(18/38) | 9x0.14 | 5.9 | 23 | 50 |

26(18/38) | 10x0.14 | 6 | 26 | 55 |

26(18/38) | 12x0.14 | 6.3 | 30 | 64 |

26(18/38) | 16x0.14 | 7.4 | 40 | 84 |

26(18/38) | 20x0.14 | 8.2 | 46 | 98 |

26(18/38) | 25x0.14 | 8.6 | 55 | 125 |

24(14/34) | 2x0.25 | 4.3 | 12 | 29 |

24(14/34) | 3x0.25 | 4.5 | 14.7 | 30 |

24(14/34) | 4x0.25 | 4.9 | 17 | 38 |

24(14/34) | 5x0.25 | 5.3 | 21.2 | 43 |

24(14/34) | 6x0.25 | 5.7 | 23.5 | 48 |

24(14/34) | 7x0.25 | 5.7 | 27.5 | 51 |

24(14/34) | 8x0.25 | 6.5 | 29.8 | 58 |

24(14/34) | 9x0.25 | 7 | 34.9 | 64 |

24(14/34) | 10x0.25 | 7.2 | 39.5 | 70 |

24(14/34) | 12x0.25 | 7.4 | 46 | 83 |

24(14/34) | 16x0.25 | 8.1 | 55.3 | 102 |

24(14/34) | 20x0.25 | 9 | 66.1 | 121 |

24(14/34) | 25x0.25 | 10.1 | 81 | 145 |

22(7/30) | 2 X 0.34 | 4.9 | 16 | 31 |

22(7/30) | 3 X 0.34 | 5.1 | 19 | 37 |

22(7/30) | 4 X 0.34 | 5.5 | 25 | 48 |

22(7/30) | 5 X 0.34 | 6.2 | 30 | 58 |

22(7/30) | 6 X 0.34 | 6.5 | 34 | 67 |

22(7/30) | 7 X 0.34 | 6.9 | 37 | 76 |

22(7/30) | 8 X 0.34 | 7.6 | 46 | 95 |

22(7/30) | 10 X 0.34 | 8.9 | 62 | 110 |

22(7/30) | 12 X 0.34 | 9.1 | 68 | 123 |

22(7/30) | 14 X 0.34 | 9.4 | 82 | 140 |

22(7/30) | 16 X 0.34 | 9.9 | 95 | 156 |

22(7/30) | 18 X 0.34 | 10.4 | 107 | 171 |

22(7/30) | 21 X 0.34 | 11.3 | 122 | 195 |

22(7/30) | 25 X 0.34 | 12.5 | 141 | 226 |

22(7/30) | 30 X 0.34 | 13.1 | 162 | 260 |

22(7/30) | 34 X 0.34 | 13.9 | 177 | 284 |

22(7/30) | 40 X 0.34 | 14.8 | 202 | 329 |

20(16/32) | 2 X 0.5 | 5.2 | 22 | 37 |

20(16/32) | 3 X 0.5 | 5.5 | 30 | 46 |

20(16/32) | 4 X 0.5 | 6.1 | 34 | 57 |

20(16/32) | 5 X 0.5 | 6.9 | 52 | 77 |

20(16/32) | 6 X 0.5 | 7.1 | 60 | 85 |

20(16/32) | 7 X 0.5 | 7.3 | 65 | 92 |

20(16/32) | 8 X 0.5 | 8.3 | 76 | 113 |

20(16/32) | 10 X 0.5 | 9.4 | 88 | 135 |

20(16/32) | 12 X 0.5 | 9.7 | 98 | 147 |

20(16/32) | 18 X 0.5 | 11.1 | 141 | 210 |

20(16/32) | 21 X 0.5 | 12.2 | 161 | 241 |

20(16/32) | 25 X 0.5 | 13.5 | 186 | 284 |

20(16/32) | 30 X 0.5 | 14.5 | 223 | 339 |

20(16/32) | 40 X 0.5 | 16.5 | 293 | 443 |

18(24/32) | 2 X 0.75 | 5.9 | 31 | 45 |

18(24/32) | 3 X 0.75 | 6.3 | 37 | 60 |

18(24/32) | 4 X 0.75 | 7.1 | 58 | 80 |

18(24/32) | 5 X 0.75 | 7.6 | 68 | 97 |

18(24/32) | 7 X 0.75 | 8.5 | 88 | 126 |

18(24/32) | 10 X 0.75 | 10.5 | 122 | 174 |

18(24/32) | 12 X 0.75 | 11.2 | 137 | 195 |

17(32/32) | 2 X 1.0 | 6.5 | 43 | 71 |

17(32/32) | 3 X 1.0 | 7.0 | 57 | 89 |

17(32/32) | 4 X 1.0 | 7.5 | 68 | 109 |

17(32/32) | 5 X 1.0 | 8.2 | 79 | 126 |

17(32/32) | 7 X 1.0 | 8.8 | 118 | 171 |

16(30/30) | 2 X 1.5 | 7.7 | 58 | 91 |

16(30/30) | 3 X 1.5 | 8.1 | 74 | 115 |

16(30/30) | 4 X 1.5 | 8.7 | 107 | 153 |

16(30/30) | 5 X 1.5 | 9.5 | 129 | 176 |

16(30/30) | 7 X 1.5 | 10.7 | 164 | 220 |

German Standard Industrial Cables LiHCH

| Application and Description | LiHCH is for use in flexible or stationary applications under low mechanical stress with free movement without any tensile stress, loads or forced movements in dry, moist and wet conditions. Commonly used as connecting cable for signal, measuring, control, call-announcing and two-way intercom systems, clock installations, electronic weighing machines and electrical apparatus for office use. The halogenfree thermoplastic jacket is flame retardant and will give off no corrosive or toxic gases in the case of fire. Commonly installed in public buildings, laboratories, trading and transportation centers. The tinned copper braid shield offers interference-free signal and data transfers. Not permitted for outdoor use. |

| Standard and Approval | VDE 0482 part 267, VDE 0812, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant |

| Cable Construction | - Plain copper conductor - Stranded to DIN VDE 0295 cl. 5, IEC 60228 cl.5 - Halogen free core insulation - Color coded to DIN 47100, but without color repetition - Plastic foil separator - 85% tinned copper braid - Halogen free outer jacket |

| Technical Characteristics | - Working voltage: 350 volts - Test voltage: 1200 volts - Minimum bending radius: 5 x Ø - Flexing temperature: -5º C to +70º C - Static temperature: -40º C to +70º C - Flame retardant: IEC 60332.1-2 - Mutual Capacitance: Conductor./conductor: 120 nF/km Conductor./shield: 160 nF/km - Halogen free: DIN EN 50267/IEC 60754 - Smoke density: DIN EN50268/IEC 61034 - Insulation resistance: 20 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² | NOMINAL OVERALL DIAMETER MM | COPPER WEIGHT KG / KM | CABLE WEIGHT KG / KM |

26(18/38) | 2x0.14 | 3.9 | 8 | 21 |

26(18/38) | 3x0.14 | 4.2 | 11 | 26 |

26(18/38) | 4x014 | 4.5 | 12.5 | 28 |

26(18/38) | 5x0.14 | 4.8 | 13.5 | 33 |

26(18/38) | 6x0.14 | 5.1 | 15.5 | 37 |

26(18/38) | 7x0.14 | 5.1 | 17 | 40 |

26(18/38) | 8x0.14 | 5.5 | 19.5 | 46 |

26(18/38) | 9x0.14 | 5.9 | 23 | 50 |

26(18/38) | 10x0.14 | 6 | 26 | 55 |

26(18/38) | 12x0.14 | 6.3 | 30 | 64 |

26(18/38) | 16x0.14 | 7.4 | 40 | 84 |

26(18/38) | 20x0.14 | 8.2 | 46 | 98 |

26(18/38) | 25x0.14 | 8.6 | 55 | 125 |

24(14/34) | 2x0.25 | 4.3 | 12 | 29 |

24(14/34) | 3x0.25 | 4.5 | 14.7 | 30 |

24(14/34) | 4x0.25 | 4.9 | 17 | 38 |

24(14/34) | 5x0.25 | 5.3 | 21.2 | 43 |

24(14/34) | 6x0.25 | 5.7 | 23.5 | 48 |

24(14/34) | 7x0.25 | 5.7 | 27.5 | 51 |

24(14/34) | 8x0.25 | 6.5 | 29.8 | 58 |

24(14/34) | 9x0.25 | 7 | 34.9 | 64 |

24(14/34) | 10x0.25 | 7.2 | 39.5 | 70 |

24(14/34) | 12x0.25 | 7.4 | 46 | 83 |

24(14/34) | 16x0.25 | 8.1 | 55.3 | 102 |

24(14/34) | 20x0.25 | 9 | 66.1 | 121 |

24(14/34) | 25x0.25 | 10.1 | 81 | 145 |

22(7/30) | 2 X 0.34 | 4.9 | 16 | 31 |

22(7/30) | 3 X 0.34 | 5.1 | 19 | 37 |

22(7/30) | 4 X 0.34 | 5.5 | 25 | 48 |

22(7/30) | 5 X 0.34 | 6.2 | 30 | 58 |

22(7/30) | 6 X 0.34 | 6.5 | 34 | 67 |

22(7/30) | 7 X 0.34 | 6.9 | 37 | 76 |

22(7/30) | 8 X 0.34 | 7.6 | 46 | 95 |

22(7/30) | 10 X 0.34 | 8.9 | 62 | 110 |

22(7/30) | 12 X 0.34 | 9.1 | 68 | 123 |

22(7/30) | 14 X 0.34 | 9.4 | 82 | 140 |

22(7/30) | 16 X 0.34 | 9.9 | 95 | 156 |

22(7/30) | 18 X 0.34 | 10.4 | 107 | 171 |

22(7/30) | 21 X 0.34 | 11.3 | 122 | 195 |

22(7/30) | 25 X 0.34 | 12.5 | 141 | 226 |

22(7/30) | 30 X 0.34 | 13.1 | 162 | 260 |

22(7/30) | 34 X 0.34 | 13.9 | 177 | 284 |

22(7/30) | 40 X 0.34 | 14.8 | 202 | 329 |

20(16/32) | 2 X 0.5 | 5.2 | 22 | 37 |

20(16/32) | 3 X 0.5 | 5.5 | 30 | 46 |

20(16/32) | 4 X 0.5 | 6.1 | 34 | 57 |

20(16/32) | 5 X 0.5 | 6.9 | 52 | 77 |

20(16/32) | 6 X 0.5 | 7.1 | 60 | 85 |

20(16/32) | 7 X 0.5 | 7.3 | 65 | 92 |

20(16/32) | 8 X 0.5 | 8.3 | 76 | 113 |

20(16/32) | 10 X 0.5 | 9.4 | 88 | 135 |

20(16/32) | 12 X 0.5 | 9.7 | 98 | 147 |

20(16/32) | 18 X 0.5 | 11.1 | 141 | 210 |

20(16/32) | 21 X 0.5 | 12.2 | 161 | 241 |

20(16/32) | 25 X 0.5 | 13.5 | 186 | 284 |

20(16/32) | 30 X 0.5 | 14.5 | 223 | 339 |

20(16/32) | 40 X 0.5 | 16.5 | 293 | 443 |

18(24/32) | 2 X 0.75 | 5.9 | 31 | 45 |

18(24/32) | 3 X 0.75 | 6.3 | 37 | 60 |

18(24/32) | 4 X 0.75 | 7.1 | 58 | 80 |

18(24/32) | 5 X 0.75 | 7.6 | 68 | 97 |

18(24/32) | 7 X 0.75 | 8.5 | 88 | 126 |

18(24/32) | 10 X 0.75 | 10.5 | 122 | 174 |

18(24/32) | 12 X 0.75 | 11.2 | 137 | 195 |

17(32/32) | 2 X 1.0 | 6.5 | 43 | 71 |

17(32/32) | 3 X 1.0 | 7.0 | 57 | 89 |

17(32/32) | 4 X 1.0 | 7.5 | 68 | 109 |

17(32/32) | 5 X 1.0 | 8.2 | 79 | 126 |

17(32/32) | 7 X 1.0 | 8.8 | 118 | 171 |

16(30/30) | 2 X 1.5 | 7.7 | 58 | 91 |

16(30/30) | 3 X 1.5 | 8.1 | 74 | 115 |

16(30/30) | 4 X 1.5 | 8.7 | 107 | 153 |

16(30/30) | 5 X 1.5 | 9.5 | 129 | 176 |

16(30/30) | 7 X 1.5 | 10.7 | 164 | 220 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.