Drop Wires No. 12, 10B, CAD55M & 10 to CW 1406, CW 1411,CW 1417 & CW 1378

| Availability: | |

|---|---|

| Quantity: | |

Drop Wires No. 12, 10B, CAD55M & 10 to CW 1406, CW 1411,CW 1417 & CW 1378

| Application | The drop wires are designed for use in local area network to link between pole and building or two buildings. The high tensile steel strength member wires are incorporated inside the cable to provide support. The cables can be used for crossing high voltage cables up to 11kV. |

| Standards | CW 1406 (Drop Wires No.12 1 pair) CW 1411 (Drop Wires No.10B 2 pairs) CW 1417 (Drop Wires CAD55M 4 pairs) CW 1378 (Drop Wires No.10 2 pairs) |

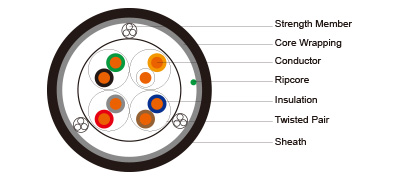

| Construction | |

| Conductors: | Solid annealed bare copper of 0.5/0.9mm as per class 1 of BS 6360/IEC 60228 |

| Insulation: | Solid low or medium density Polyethylene (CW 1406, CW 1411 & CW 1417) or Polyvinyl Chloride (CW 1378) to BS 7878 |

| Core Wrapping: | 23 micron Polyester Tape |

| Strength Member: | 1 Pair: 1 element of 3 x 0.41mm brass coated steel strength member; PVC insulated to 1.4mm 2 & 4 Pairs: 3 elements of 3 x 0.25mm brass coated steel strength member; PVC insulated to 1.0mm |

| Sheath: | Black medium density polyethylene as per BS 7878 |

| Ripcord: | Nylon |

Electrical Properties

Nominal Conductor Diameter | mm | 0.9 | 0.5 | 0.5 | 0.5 |

BT Drop Wire Reference | No.12 | No.10 | No.10B | CAD55M | |

Standard | CW 1406 | CW 1378 | CW 1411 | CW 1417 | |

Number of Pairs | 1 | 2 | 2 | 4 | |

Maximum Conductor Resistance @20°C | Ω/km | 28 | 95 | 95 | 95 |

Minimum Insulation Resistance @500V DC | MΩ.km | 10000 | 100 | 10000 | 10000 |

Breaking Load | N | 1350-1550 | 1350-1550 | 1350-1550 | 1350-1550 |

Maximum Mutual Capacitance @0.8KHz-3.0KHz | nF/km | - | 100 | 56 | 56 |

Maximum Capacitance Unbalance pair-to-pair | pF/500m | - | 500 | 275 | 300 |

Mechanical and Thermal Properties

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 7.5 x Overall Diameter

Color Code

CW 1406 Pair 1: Orange/White | |

CW 1411 Pair 1: Orange/White | Pair 2: Green/Black |

CW 1417 Pair 1: Orange/White | Pair 2: Red/Grey |

Pair 3: Blue/Brown | Pair 4: Green/Black |

CW 1378 Pair 1: Orange/White | Pair 2: Green/Black |

Dimensions And Weight

Cable Code | Number of Pairs | Insulation Material | Nominal Insulation Thickness mm | Minimum Sheath Thickness mm | Min/Max Overall Diameter mm | Nominal Weight kg/km |

0.5mm Conductor | ||||||

UE-TP1411-2Y2Y-2P05-DW10B | 2 | PE | 0.2 | 0.4 | 5.1/5.6 | 32 |

UE-TP1417-2Y2Y-4P05-DW55M | 4 | PE | 0.2 | 0.5 | 5.3/5.5 | 35 |

UE-TP1378-Y2Y-2P05-DW10 | 2 | PVC | 0.2 | 0.4 | 5.3/5.5 | 33 |

0.9mm Conductor | ||||||

UE-TP1406-2Y2Y-1P09-DW12 | 1 | PE | 0.3 | 0.5 | 5.0/5.5 | 32 |

Drop Wires No. 12, 10B, CAD55M & 10 to CW 1406, CW 1411,CW 1417 & CW 1378

| Application | The drop wires are designed for use in local area network to link between pole and building or two buildings. The high tensile steel strength member wires are incorporated inside the cable to provide support. The cables can be used for crossing high voltage cables up to 11kV. |

| Standards | CW 1406 (Drop Wires No.12 1 pair) CW 1411 (Drop Wires No.10B 2 pairs) CW 1417 (Drop Wires CAD55M 4 pairs) CW 1378 (Drop Wires No.10 2 pairs) |

| Construction | |

| Conductors: | Solid annealed bare copper of 0.5/0.9mm as per class 1 of BS 6360/IEC 60228 |

| Insulation: | Solid low or medium density Polyethylene (CW 1406, CW 1411 & CW 1417) or Polyvinyl Chloride (CW 1378) to BS 7878 |

| Core Wrapping: | 23 micron Polyester Tape |

| Strength Member: | 1 Pair: 1 element of 3 x 0.41mm brass coated steel strength member; PVC insulated to 1.4mm 2 & 4 Pairs: 3 elements of 3 x 0.25mm brass coated steel strength member; PVC insulated to 1.0mm |

| Sheath: | Black medium density polyethylene as per BS 7878 |

| Ripcord: | Nylon |

Electrical Properties

Nominal Conductor Diameter | mm | 0.9 | 0.5 | 0.5 | 0.5 |

BT Drop Wire Reference | No.12 | No.10 | No.10B | CAD55M | |

Standard | CW 1406 | CW 1378 | CW 1411 | CW 1417 | |

Number of Pairs | 1 | 2 | 2 | 4 | |

Maximum Conductor Resistance @20°C | Ω/km | 28 | 95 | 95 | 95 |

Minimum Insulation Resistance @500V DC | MΩ.km | 10000 | 100 | 10000 | 10000 |

Breaking Load | N | 1350-1550 | 1350-1550 | 1350-1550 | 1350-1550 |

Maximum Mutual Capacitance @0.8KHz-3.0KHz | nF/km | - | 100 | 56 | 56 |

Maximum Capacitance Unbalance pair-to-pair | pF/500m | - | 500 | 275 | 300 |

Mechanical and Thermal Properties

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 7.5 x Overall Diameter

Color Code

CW 1406 Pair 1: Orange/White | |

CW 1411 Pair 1: Orange/White | Pair 2: Green/Black |

CW 1417 Pair 1: Orange/White | Pair 2: Red/Grey |

Pair 3: Blue/Brown | Pair 4: Green/Black |

CW 1378 Pair 1: Orange/White | Pair 2: Green/Black |

Dimensions And Weight

Cable Code | Number of Pairs | Insulation Material | Nominal Insulation Thickness mm | Minimum Sheath Thickness mm | Min/Max Overall Diameter mm | Nominal Weight kg/km |

0.5mm Conductor | ||||||

UE-TP1411-2Y2Y-2P05-DW10B | 2 | PE | 0.2 | 0.4 | 5.1/5.6 | 32 |

UE-TP1417-2Y2Y-4P05-DW55M | 4 | PE | 0.2 | 0.5 | 5.3/5.5 | 35 |

UE-TP1378-Y2Y-2P05-DW10 | 2 | PVC | 0.2 | 0.4 | 5.3/5.5 | 33 |

0.9mm Conductor | ||||||

UE-TP1406-2Y2Y-1P09-DW12 | 1 | PE | 0.3 | 0.5 | 5.0/5.5 | 32 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.