300/500V Mica+XLPE Insulated, LSZH Sheathed fire resistant Power Cables (Single Core)

| Availability: | |

|---|---|

| Quantity: | |

300/500V Mica+XLPE Insulated, LSZH Sheathed fire resistant Power Cables (Single Core)

FR200P 05M2XH-R (CU/MGT+XLPE/LSZH 300/500V Class 2)

| Application: | These cables are designed for areas where the integrity of the electrical circuit is critical in maintaining power supply. Applications can be found in emergency lightings, control and power circuits, power stations, fire alarm systems, underground tunnels, lifts, escalators, and high-rise buildings. |

| STANDARDS: | Basic design to IEC 60502-1 |

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387 CWZ; DIN VDE 0472-814(FE180); CEI 20-36/2-1; SS229-1; NBN C 30-004 (cat. F3); NF C32-070-2.3(CR1) |

System circuit integrity | DIN 4102-12, E30 depending on lay system |

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

Minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

No Toxic gases | NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

300/500 V

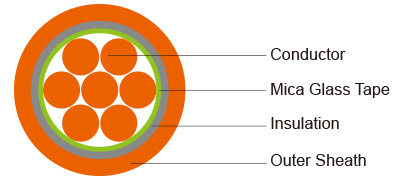

CABLE CONSTRUCTION

1 Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

2 Insulation: Mica glass tape covered by extruded cross-linked XLPE compound

3 Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH

compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -30°C – +90°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 8 x Overall Diameter

Electrical PROPERTIES

Dielectric test: | 2000 V r.m.s. x 5' (core/core) |

Insulation resistance | 1000 MΩ x km (at 20°C) |

Short circuit temperature | 250°C |

CONSTRUCTION PARAMETERS

Conductor | |||||

Nominal Cross Section Area | No./ Nominal Diameter of trands | Nominal Insulation Thickness | Nominal Sheath Thickness | Without Earth Conductor | |

Nominal Overall Diameter | Approx. Weight | ||||

mm2 | No./mm | mm | mm | mm | kg/km |

1.5 | 7/0.53 | 0.5 | 0.5 | 4.4 | 29 |

2.5 | 7/0.67 | 0.5 | 0.5 | 4.9 | 40 |

4 | 7/0.85 | 0.5 | 0.5 | 5.5 | 55 |

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor crosssection area | Reference Method 4 (enclosed in conduit in thermally insulating wall etc) | Reference Method 3 (enclosed in conduit on a wall or in trunking etc) | Reference Method 1 (clipped direct) | Reference Method 11 (on a perforated cable tray, horizontal or vertical) | Reference Method 12 (free air) | ||||||

Horizontal flat spaced | Vertical flat spaced | Trefoil | |||||||||

2 cables, single-phase a.c. or d.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single- | 3 or 4 cables, 3-phase a.c. | 2 cables, single-phase a.c. or d.c. flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single -phase a.c. or d.c. or flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single-phase a.c. or d.c. or 3 cables three phase | 2 cables, single-phase a.c. or d.c. or 3 cables three phase | 3 cables, trefoil 3-phase phase a.c. | |

phase a.c. a.c. or d.c | |||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

mm2 | A | A | A | A | A | A | A | A | A | A | A |

1.5 | 18 | 17 | 22 | 19 | 25 | 23 | - | - | - | - | - |

2.5 | 24 | 23 | 30 | 26 | 34 | 31 | - | - | - | - | - |

4 | 33 | 30 | 40 | 35 | 46 | 41 | - | - | - | - | - |

Voltage Drop (Per Amp Per Meter)

Nominal Cross Section Area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | |||

Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1 and 11 (clipped direct or on trays touching) | Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1, | Ref. Methods 1 and 11 | ||

11 and 12 (in trefoil) | (Flat and touching) | |||||

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm2 | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

1.5 | 31 | 31 | 27 | 27 | 27 | 27 |

2.5 | 19 | 19 | 16 | 16 | 16 | 16 |

4 | 33 | 12 | 10 | 10 | 10 | 10 |

300/500V Mica+XLPE Insulated, LSZH Sheathed fire resistant Power Cables (Single Core)

FR200P 05M2XH-R (CU/MGT+XLPE/LSZH 300/500V Class 2)

| Application: | These cables are designed for areas where the integrity of the electrical circuit is critical in maintaining power supply. Applications can be found in emergency lightings, control and power circuits, power stations, fire alarm systems, underground tunnels, lifts, escalators, and high-rise buildings. |

| STANDARDS: | Basic design to IEC 60502-1 |

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387 CWZ; DIN VDE 0472-814(FE180); CEI 20-36/2-1; SS229-1; NBN C 30-004 (cat. F3); NF C32-070-2.3(CR1) |

System circuit integrity | DIN 4102-12, E30 depending on lay system |

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

Minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

No Toxic gases | NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

300/500 V

CABLE CONSTRUCTION

1 Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

2 Insulation: Mica glass tape covered by extruded cross-linked XLPE compound

3 Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH

compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -30°C – +90°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 8 x Overall Diameter

Electrical PROPERTIES

Dielectric test: | 2000 V r.m.s. x 5' (core/core) |

Insulation resistance | 1000 MΩ x km (at 20°C) |

Short circuit temperature | 250°C |

CONSTRUCTION PARAMETERS

Conductor | |||||

Nominal Cross Section Area | No./ Nominal Diameter of trands | Nominal Insulation Thickness | Nominal Sheath Thickness | Without Earth Conductor | |

Nominal Overall Diameter | Approx. Weight | ||||

mm2 | No./mm | mm | mm | mm | kg/km |

1.5 | 7/0.53 | 0.5 | 0.5 | 4.4 | 29 |

2.5 | 7/0.67 | 0.5 | 0.5 | 4.9 | 40 |

4 | 7/0.85 | 0.5 | 0.5 | 5.5 | 55 |

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor crosssection area | Reference Method 4 (enclosed in conduit in thermally insulating wall etc) | Reference Method 3 (enclosed in conduit on a wall or in trunking etc) | Reference Method 1 (clipped direct) | Reference Method 11 (on a perforated cable tray, horizontal or vertical) | Reference Method 12 (free air) | ||||||

Horizontal flat spaced | Vertical flat spaced | Trefoil | |||||||||

2 cables, single-phase a.c. or d.c. | 3 or 4 cables, 3-phase a.c. | 2 cables, single- | 3 or 4 cables, 3-phase a.c. | 2 cables, single-phase a.c. or d.c. flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single -phase a.c. or d.c. or flat and touching | 3 or 4 cables, 3-phase a.c. flat and touching or trefoil | 2 cables, single-phase a.c. or d.c. or 3 cables three phase | 2 cables, single-phase a.c. or d.c. or 3 cables three phase | 3 cables, trefoil 3-phase phase a.c. | |

phase a.c. a.c. or d.c | |||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

mm2 | A | A | A | A | A | A | A | A | A | A | A |

1.5 | 18 | 17 | 22 | 19 | 25 | 23 | - | - | - | - | - |

2.5 | 24 | 23 | 30 | 26 | 34 | 31 | - | - | - | - | - |

4 | 33 | 30 | 40 | 35 | 46 | 41 | - | - | - | - | - |

Voltage Drop (Per Amp Per Meter)

Nominal Cross Section Area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | |||

Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1 and 11 (clipped direct or on trays touching) | Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) | Ref. Methods 1, | Ref. Methods 1 and 11 | ||

11 and 12 (in trefoil) | (Flat and touching) | |||||

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm2 | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

1.5 | 31 | 31 | 27 | 27 | 27 | 27 |

2.5 | 19 | 19 | 16 | 16 | 16 | 16 |

4 | 33 | 12 | 10 | 10 | 10 | 10 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Tel : +8613964006035

E-mail : jnhjkd@163.com

WhatsApp:+8618396877830

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.