You are here: Home / Products / Wire and Cables / BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES / 150/250V HF-EPR Insulated, SW2/SW4 Sheathed, Collectively Screened Unarmoured Flame Retardant Instrumentation & Control Cables

150/250V HF-EPR Insulated, SW2/SW4 Sheathed, Collectively Screened Unarmoured Flame Retardant Instrumentation & Control Cables

150/250V HF-EPR Insulated, SW2/SW4 Sheathed, Collectively Screened Unarmoured Flame Retardant Instrumentation & Control Cables

| Availability: | |

|---|---|

| Quantity: | |

150/250V HF-EPR Insulated, SW2/SW4 Sheathed, Collectively Screened Unarmoured Flame Retardant Instrumentation & Control Cables

| Application: | These elastomeric insulated cables are designed for fixed wiring in ships and on mobile offshore units, suitable for use in instrumentation, lighting and control circuits. |

| Standards: | BS 6883 IEC 60332-3A Flame retardant IEC 60754-1; IEC 60754-2 Corrosivity IEC 61034-2 Smoke density Cold bend and impact (-40°C) (on request) CSA C22.2 No. 38-95 (on request) |

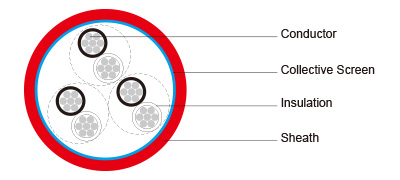

| Construction: | Conductor: Tinned copper wire stranded circular cl. 2 BS 6360/IEC 60228. Insulation: HF-EPR GP4 according to BS 7655 1.2. Lay-up: Pairs, triples, quads. Individual Screen: Aluminium/polyester tape + drain wire tinned copper. Sheath: Halogen free thermosetting compound SW4 according to BS 7655 2.6 or reduced halogen thermosetting compound SW2 according to BS 7655 2.6. |

| Mechanical and Thermal Properties: | Minimum Internal Bending Radius: 8×OD Temperature Range: -40℃ ~ +90℃ |

Dimensions and Weight

Insulation Colour Scheme

| Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Minimum Overall Diameter mm | Maximum Overall Diameter mm | Approx. Weight kg/km |

| Multipair | |||||

| 3×2×0.75 | 0.8 | 1.2 | 12.6 | 14.5 | 175 |

| 7×2×0.75 | 0.8 | 1.4 | 16.6 | 18.7 | 330 |

| 12×2×0.75 | 0.8 | 1.6 | 21.7 | 24.2 | 530 |

| 20×2×0.75 | 0.8 | 1.8 | 27.3 | 30.1 | 830 |

| 27×2×0.75 | 0.8 | 1.9 | 31.1 | 34.2 | 1070 |

| 37×2×0.75 | 0.8 | 2.1 | 34.4 | 37.7 | 1430 |

| 3×2×1 | 0.8 | 1.2 | 13.3 | 15.3 | 185 |

| 7×2×1 | 0.8 | 1.4 | 17.6 | 19.8 | 360 |

| 12×2×1 | 0.8 | 1.6 | 23.1 | 25.7 | 590 |

| 20×2×1 | 0.8 | 1.8 | 29.1 | 31.9 | 920 |

| 27×2×1 | 0.8 | 2.0 | 33.3 | 36.6 | 1220 |

| 37×2×1 | 0.8 | 2.2 | 36.9 | 40.3 | 1630 |

| Multitriple | |||||

| 3×3×0.75 | 0.8 | 1.3 | 14.2 | 16.2 | 230 |

| 7×3×0.75 | 0.8 | 1.4 | 19.4 | 21.9 | 440 |

| 12×3×0.75 | 0.8 | 1.7 | 24.2 | 26.8 | 730 |

| 3×3×1 | 0.8 | 1.3 | 15.1 | 17.1 | 260 |

| 7×3×1 | 0.8 | 1.5 | 20.9 | 23.4 | 510 |

| 12×3×1 | 0.8 | 1.7 | 25.8 | 28.5 | 840 |

<template class="visibility">

150/250V HF-EPR Insulated, SW2/SW4 Sheathed, Collectively Screened Unarmoured Flame Retardant Instrumentation & Control Cables

| Application: | These elastomeric insulated cables are designed for fixed wiring in ships and on mobile offshore units, suitable for use in instrumentation, lighting and control circuits. |

| Standards: | BS 6883 IEC 60332-3A Flame retardant IEC 60754-1; IEC 60754-2 Corrosivity IEC 61034-2 Smoke density Cold bend and impact (-40°C) (on request) CSA C22.2 No. 38-95 (on request) |

| Construction: | Conductor: Tinned copper wire stranded circular cl. 2 BS 6360/IEC 60228. Insulation: HF-EPR GP4 according to BS 7655 1.2. Lay-up: Pairs, triples, quads. Individual Screen: Aluminium/polyester tape + drain wire tinned copper. Sheath: Halogen free thermosetting compound SW4 according to BS 7655 2.6 or reduced halogen thermosetting compound SW2 according to BS 7655 2.6. |

| Mechanical and Thermal Properties: | Minimum Internal Bending Radius: 8×OD Temperature Range: -40℃ ~ +90℃ |

Dimensions and Weight

Insulation Colour Scheme

| Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Minimum Overall Diameter mm | Maximum Overall Diameter mm | Approx. Weight kg/km |

| Multipair | |||||

| 3×2×0.75 | 0.8 | 1.2 | 12.6 | 14.5 | 175 |

| 7×2×0.75 | 0.8 | 1.4 | 16.6 | 18.7 | 330 |

| 12×2×0.75 | 0.8 | 1.6 | 21.7 | 24.2 | 530 |

| 20×2×0.75 | 0.8 | 1.8 | 27.3 | 30.1 | 830 |

| 27×2×0.75 | 0.8 | 1.9 | 31.1 | 34.2 | 1070 |

| 37×2×0.75 | 0.8 | 2.1 | 34.4 | 37.7 | 1430 |

| 3×2×1 | 0.8 | 1.2 | 13.3 | 15.3 | 185 |

| 7×2×1 | 0.8 | 1.4 | 17.6 | 19.8 | 360 |

| 12×2×1 | 0.8 | 1.6 | 23.1 | 25.7 | 590 |

| 20×2×1 | 0.8 | 1.8 | 29.1 | 31.9 | 920 |

| 27×2×1 | 0.8 | 2.0 | 33.3 | 36.6 | 1220 |

| 37×2×1 | 0.8 | 2.2 | 36.9 | 40.3 | 1630 |

| Multitriple | |||||

| 3×3×0.75 | 0.8 | 1.3 | 14.2 | 16.2 | 230 |

| 7×3×0.75 | 0.8 | 1.4 | 19.4 | 21.9 | 440 |

| 12×3×0.75 | 0.8 | 1.7 | 24.2 | 26.8 | 730 |

| 3×3×1 | 0.8 | 1.3 | 15.1 | 17.1 | 260 |

| 7×3×1 | 0.8 | 1.5 | 20.9 | 23.4 | 510 |

| 12×3×1 | 0.8 | 1.7 | 25.8 | 28.5 | 840 |

Product Category

- Connector & Terminals

- EV Charging Plug

- Handheld Tape Wrapping Machine

- Injection molding

- NPS Spools Plastic Spools

- Wire and Cables

- 0.6/1KV POWER CABLE TO IEC60502

- ALARM & AUDIO & ELECTRONIC CABLES

- AUTOMOTIVE CABLES TO ISO6722, SAEJ1128, JASO D611

- BELDEN ALTERNATIVE CABLES

- BS 6883&BS7917 STANDARD OFFSHORE & MARINE CABLES

- BUS CABLES TO BS EN/IEC61158 EIA RS485

- COAXIAL CABLES

- FIRE RESISTING CABLE TO IEC60331, BS6387, SS299

- IEC60092 STANDARD OFFSHORE & MARINE CABLES

- INDUSTRIAL CABLES

- INSTRUMENT CABLES

- LSZH SHEATH FLAME RETARDANT CABLE TO IEC60332

- MEDIUM VOLTAGE CABLES TO IEC60502, BS6622, VDE0276

- MINING CABLES TO ICEA/AS/NIS/VDE STANDARD

- NEK606 OFFSHORE & MARINE CABLES

- PVC SHEATH FLAME RETARDANT CABLE TO IEC60332

- SHIPBOARD CABLES(JIS)

- TELEPHONE CABLES

- THERMOCOUPLE CABLES

- Wire Harness/Wiring Harness

Contact Us

Add : Youth Enterprenership Park No. 1313, Shuangshan Street, Zhangqiu District, Jinan City, Shandong Province.

Tel : +8613964006035

E-mail : jnhjkd@163.com

Tel : +8613964006035

E-mail : jnhjkd@163.com

hjmouldtech@gmail.com

WhatsApp:+8618396877830

WhatsApp:+8618396877830

An important note.

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.

Dear friend, inquiries we will reply to you within 24 hours (48 hours at the latest), if you have not received a reply, please check your email spam folder, it may be in there. Thank you for your attention and support to our company.